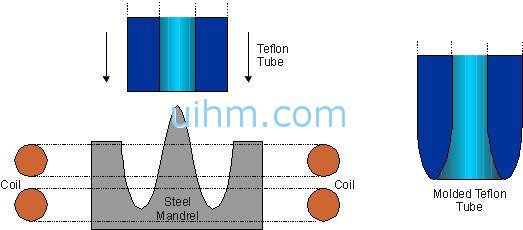

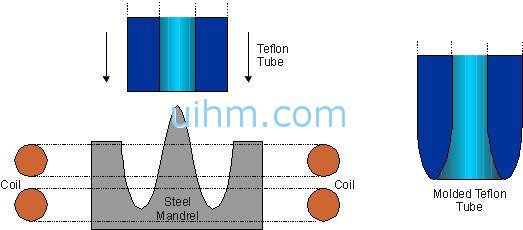

Induction Molding for teflon catheter tip

Views Send Enquiry

Objective Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip.

Material Teflon catheter tubing, mandrel assembly

Temperature 600-700°F (315-371ºC)

Frequency 376 kHz

Equipment 6 KW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A two turn coil is used to heat the steel mandrel to 660ºF (371ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip.

Results/Benefits Induction heating provides:

• Precise, repeatable application of heat

• Non-contact heating

• Faster cycle times

Good

Bad

Related Content

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment