Induction Heating catheter tipping die

Views Send Enquiry

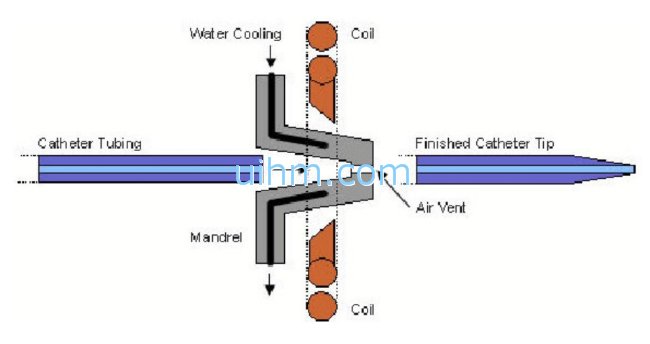

Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller.

Material materials, supplies involved in the application

Temperature 400°F (204°C)

Frequency 325kHz

Equipment 14KW induction heating system, remote heat station containing one 0.66 microfarad capacitor.

Process A two turn plate concentrator coil is used to heat the die. To measure the temperature on the ID and establish the time-totemperature relationship, the thermocouple is inserted inside the brass die. RF power is applied for 3 seconds to heat the die to 400°F (204°C). The nylon tube is pushed into the die and formed into a catheter.

Results/Benefits Induction heating provides:

• Increased throughput and reduced cycle time

• Consistent and repeatable results

• Clean heating

• Precise temperature control

Induction Heating catheter tipping die

Good

Bad

Related Content

induction heating steel plate by pancake induction coil

induction heating steel knife

induction heating steel pipes by water cooled flexible induction coil and 120KW RF induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating inner surface

induction heating steel plate

induction heating stator frame

induction heating graphite mould

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment