-

Keywords"or",total

1005 records

-

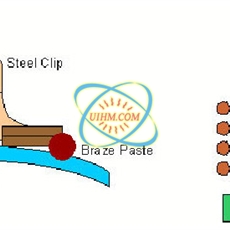

induction brazing steel orthodontic parts

Objective To heat a batch of orthodontic parts to 1300F (704C) within 1 second in an inert atmosphere for brazing. Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) cen…

-

induction annealing motor shaft

Objective Annealing the end of a steel hydraulic motor shaft prior to machining Material .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end Temperature 1350 F (732 C) Frequency 359 kHz Equipment • UM-06A-UHF induction heating…

-

induction surface quenching works

Induction quenching is the process of quenching steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of quenching can be…

-

how induction brazing works

Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process will involve temperature more…

-

induction cooktops save energy, save money for you

An induction cooktop is a cooker which integrates vibrating magnetic energy to create heat. With induction, the heat generated used right into the cooking vessel instead of getting hot through flamable gas or electric coils. The heating vessel used for an …

-

film capacitor module in the application of induction heating system

Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began …

-

heat treating forgings

Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity. The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac …

-

inductor (induction coil) designing

It is within the inductor that the varying magnetic field required for induction heating is developed, through the flow of alternating current. (Induction Coil) design is therefore one of the most important aspects of the overall induction heating machine.…

-

simulation of faradays law from university of colorado boulder

Click to Run

-

enquiry details form to uihm

Enquiry Details Form CompanyName Attn(Email/Tel) Abstract of your requirement IntentionType from UIHM * The redoptions are important, black ones are optional in below table:ItemDetails ofApplicationDescription(photos or drawings attached will be bet…