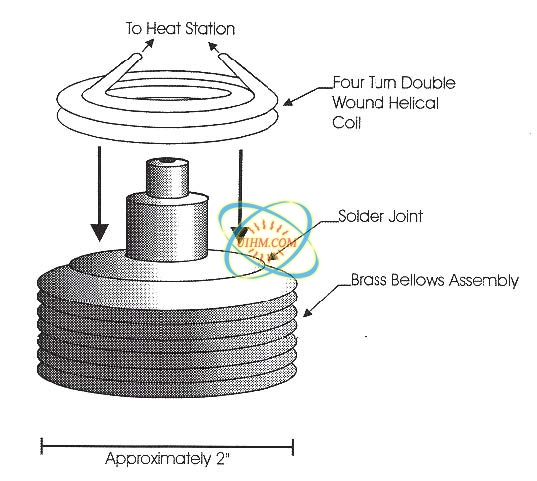

Induction Soldering Brass Bellows Assembly

Views Send Enquiry

Objective: To heat a brass bellows and end cap assembly to 450°F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality solder joint with minimal heating of the bellows to prevent annealing and performance losses. Solder preforms, in the form of flat washers, are to be used to complete this application.

Material: Brass Bellows measuring 2″ in diameter

Solder Preforms

Cadmium Free Flux

Temperature: 450°F

Application: The Power of 10KW,10kW output solid state induction power supply along with a unique three (3) turn double wound helical coil was utilized to achieve the following results:

* 450°F was reached and solder flow completed in 6.3 seconds.

* A quality repeatable solder joint was observed.

Equipment: Power of 10KW,10kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn double wound helical coil with an inside diameter of 0.4″.

Frequency: 307 kHz

Soldering Brass Bellows Assembly

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

UHF handheld induction heater for brazing copper

UHF handheld induction heater for brazing brass

handheld induction coil for soldering brass

handheld induction coil for brazing brass

induction brass soldering for refrigerator pipes

induction brass soldering with D80mm red copper with 60% silver solder paste

induction brass soldering pipes for chiller

induction brass soldering for multi pipes

Newest Comment

No Comment

Post Comment