Induction Heating Inconnel Susceptor

Views Send Enquiry

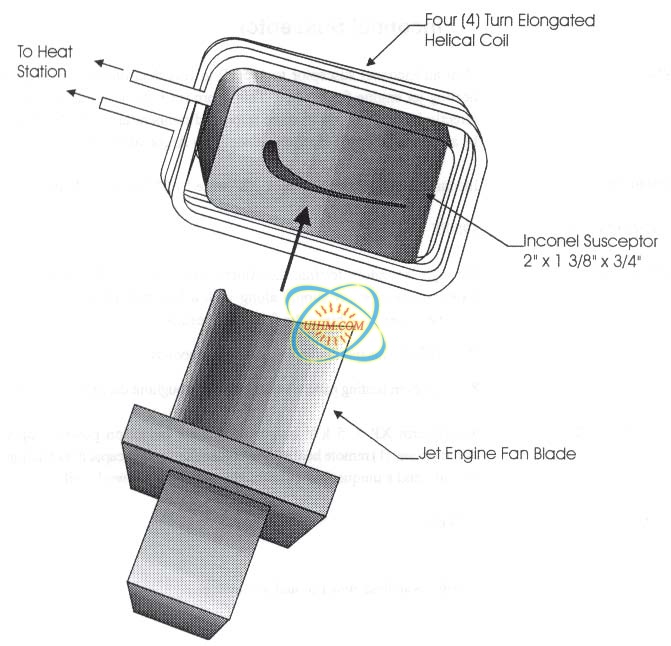

Objective: Heat an Inconnel susceptor to 19500F in less than one (1) minute for heating jet engine fan blades. This approach is to be used, instead of directly heating the blade, since improved temperature uniformity will be achieved. Heating is to take place in an Argon atmosphere.

Material: Inconnel Susceptor measuring 1 3/8″ wide by 2″ long by 3/4″ thick

Temperature: 19500F

Application: Through laboratory testing, the Power of 10KW,10kW output solid state induction power supply along with a four turn elongated helical coil were used to achieve the following results:

# 19500F was reached in forty five (45) seconds.

# An even heating pattern was observed throughout the Inconnel block

Equipment: Power of 10KW,10kW output solid state induction power supply including one (1) remote heat station containing two (2) capacitors with a total value of 0.66 μF, and a unique four (4) turn elongated helical work coil.

Frequency: 215 kHz

heating Inconnel Susceptor

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment